Using “Missing On-hand”

When an

item that is supposed to be in stock and available has been allocated on an

order but cannot be located, CODIS can put the missing allocated quantity into

the “missing on-hand” field in the respective stock file record. This

reduces the available quantity of the item and thus may prevent allocation to

another order or the release of the backorder that’s being created from the

current order the next time a backorder allocation runs, thus preventing

another trip to the bin for the “missing” item.

Using the “Missing On-hand” feature in CODIS requires some

setup to be done before it becomes functional.

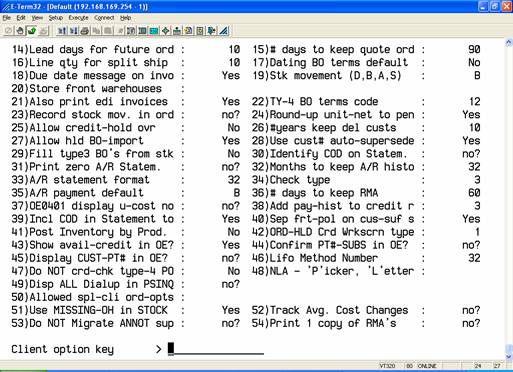

Step 1 is to edit field 51 of the “Client Options” codes

record to “Y”.

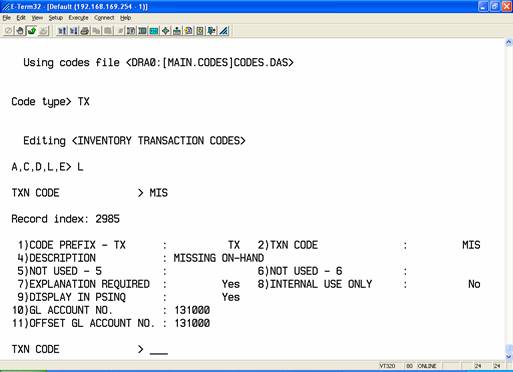

Step 2 is to add a “TX” codes record similar to the one

below, except using your GL account for “Inventory” instead of the one indicated in the

screenshot.

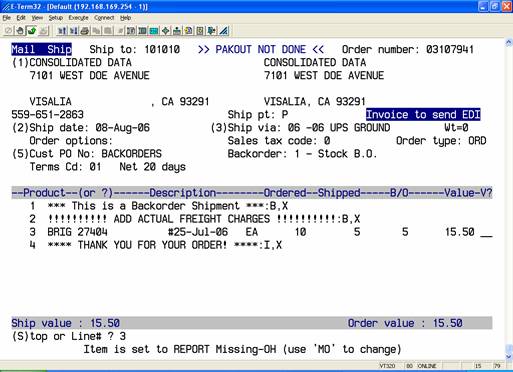

Setup is complete. Now, when you finalize an order (via Pick Ticket Exceptions/Invoice)

and you change the actual quantity shipped to something less than the quantity

that was allocated, CODIS will add the difference to the ‘Missing On Hand’

field in the Stock File, it will also leave that quantity allocated and

therefore it will not show as ‘available to ship’.

You can override this behavior

by typing ‘MO’ at the ‘Verify’ prompt. You will want to do this override if you

intentionally ship less than what was allocated (part number in short supply).

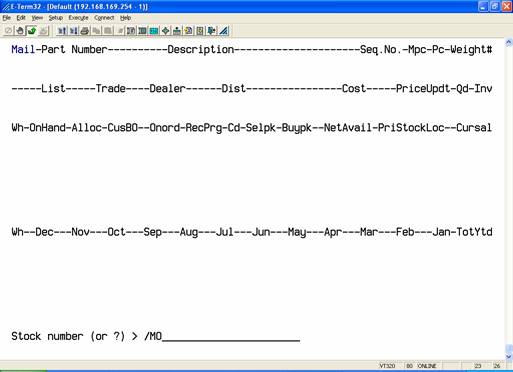

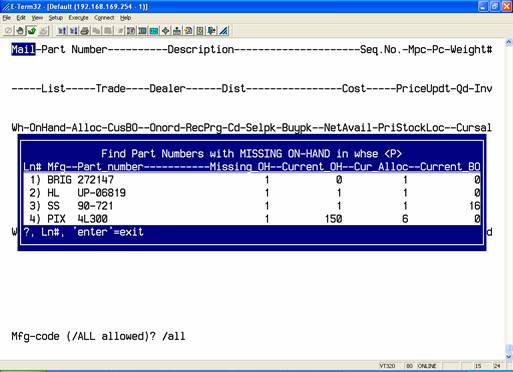

To get a listing of items with a “missing on-hand” you can

use the “/MO” option in Product Stock Inquiry.

Enter the shipping warehouse you want to list. Enter the manufacturer code you want to list

or “/ALL”.

A report can be printed from the display by typing “//P”

<enter> then selecting the printer.

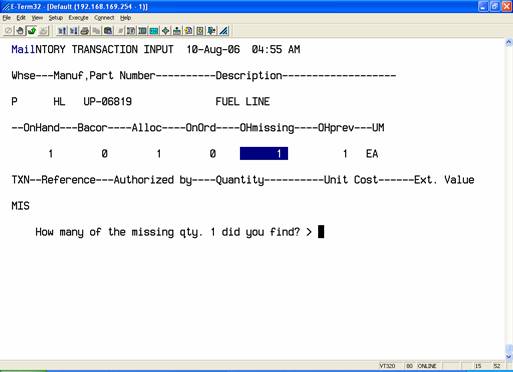

When you either find or don’t find the missing quantity,

you can update your stock file record by using the Inventory Adjustments

program, 20/10 from the main menu. The

transaction code you enter at the “TXN” prompt will be “MIS” (the new code you

added in step 2).

The item in the screenshot shows a ‘Missing On

Hand’ quantity of 1 and a ‘On Hand’ quantity of 1.

When you physically check stock, you confirm that the part is missing. When you

enter the ‘MIS’ transaction, the program asks ‘How many of the missing parts

did you find?’. Since the part is in fact missing, you

would enter ‘0’.

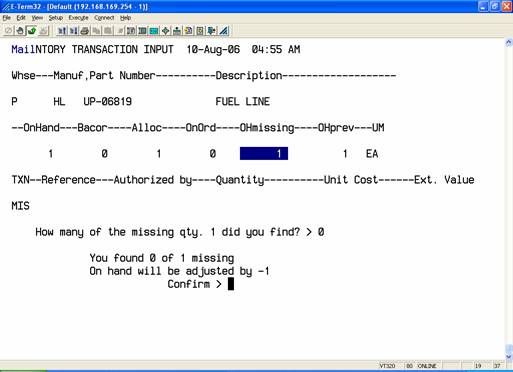

The program informs you that the adjustment will be

‘-1’ and asks you to confirm. When you confirm, the program reduces the the ‘On Hand’ quantity, the ‘Allocated’ quantity and the

‘Missing On Hand’ quantity by 1.

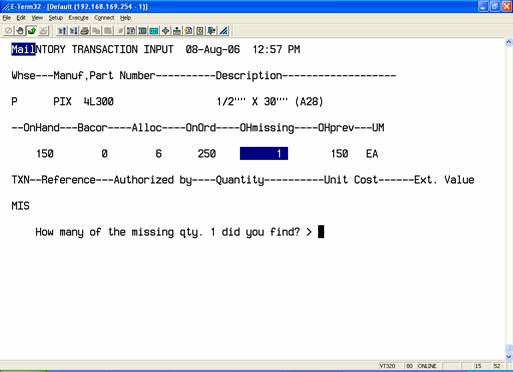

The item in example 2 shows a ‘Missing On Hand’

quantity of 1 and an ‘On Hand’ quantity of 150. There could be one of several different

resolutions for this condition.

When you physically check

stock, you find 150 of the part in a different part of the warehouse (the order

filler didn’t find them so he zeroed the item). In that case, when you make the

‘MIS’ adjustment you answer the question ‘How many of the missing part did you

find?’ as ‘1’. The program now reduces the ‘Missing On Hand’ quantity and the

‘Allocated’ quantity by 1 and it leaves the ‘On Hand’ quantity at 150.

When you physically check stock

you find 0. In this case you would make the ‘MIS’ adjustment and answer the

question ‘How many of the missing part did you find?’ as ‘0’. This reduces the

‘Missing on Hand’ quantity, the ‘On Hand’ quantity, and the ‘Allocated’

quantity by 1. Next you make an ‘ADJ’ adjustment for ‘-149’ to reduce the ‘On

Hand’ quantity to 0.

When you physically check stock

you find none in the primary location, but you find 50 somewhere else in the

warehouse. In this case you would make the ‘MIS’ adjustment and answer the

question ‘How many of the missing part did you find?’ as ‘0’. This reduces the

‘Missing on Hand’ quantity, the On Hand quantity, and the Allocated quantity by

1. Next you make an ‘ADJ’ adjustment for -99 to reduce the On Hand quantity to

50.