Creating a Model Order for Building Kits

Occasionally you may want

to use several individual parts to create a kit. You can adjust the inventory, removing the

items from stock that makeup the kit and add the kit part number to stock. This is time consuming and lends itself to

keying error. Also the request to makeup

the kit becomes external to the system.

An option is to a pick ticket that tells the warehouse to remove the component

items then create and restock the kit.

When the pick ticket is finished through the exceptions/invoicing

program all item quantities are adjusted accordingly.

The steps are as follows:

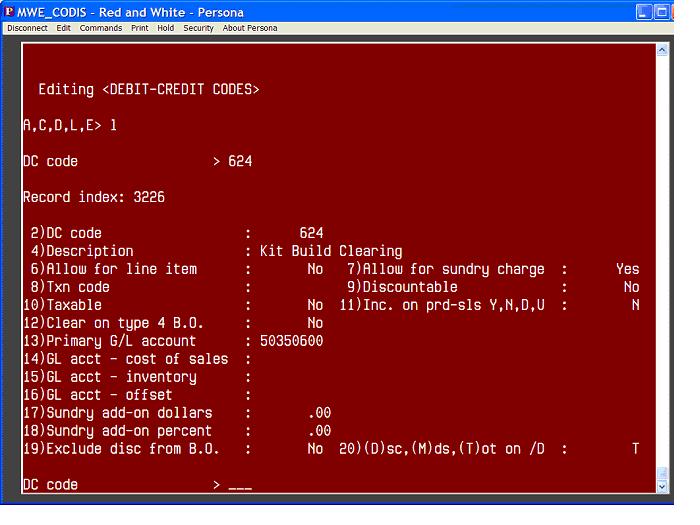

Setup a DC codes record

for “

Here’s an example:

Setup a DC codes record for

“Kit Build Clearing” that serves to clear any difference between your cost of

the components and the kit cost to the GL account specified in field #13 of the

example below.

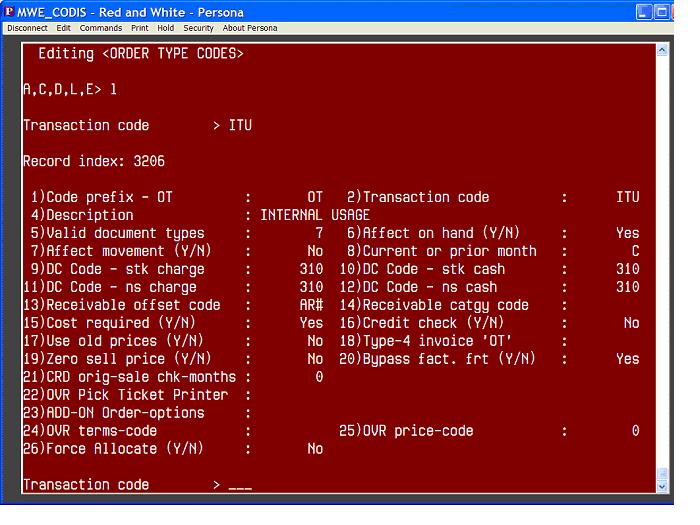

Setup an Order Type codes

record, “ITU”, for “Internal Usage Only”

using the DC code you just setup for “

Here’s an example:

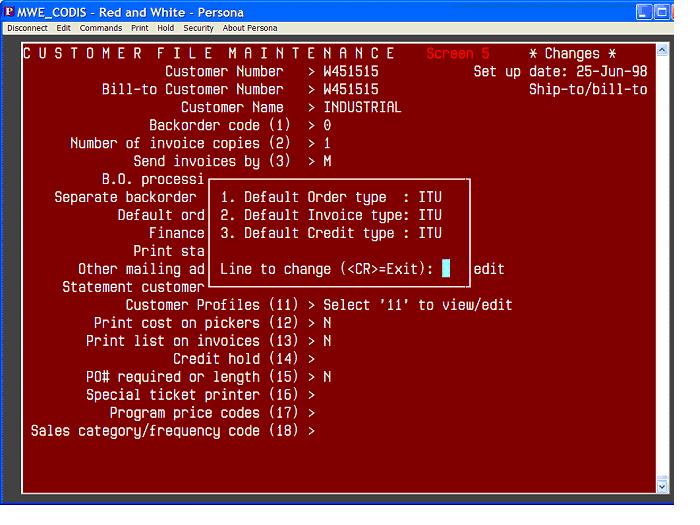

Setup a customer record

for “Internal Usage” making the default order/credit/invoice type “ITU”.

Here’s an example:

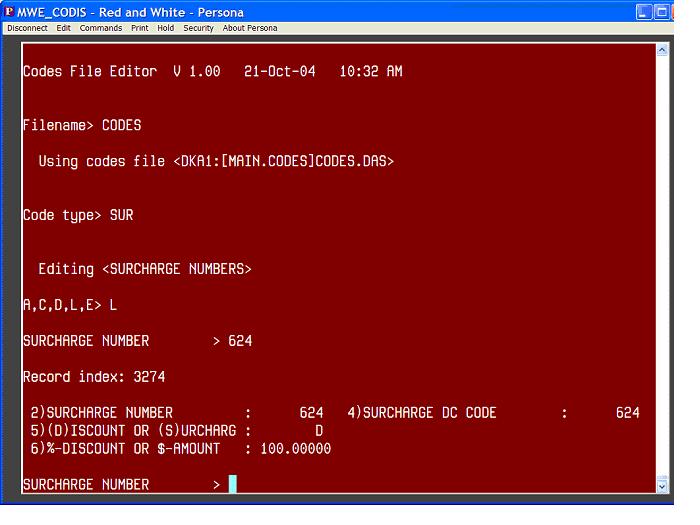

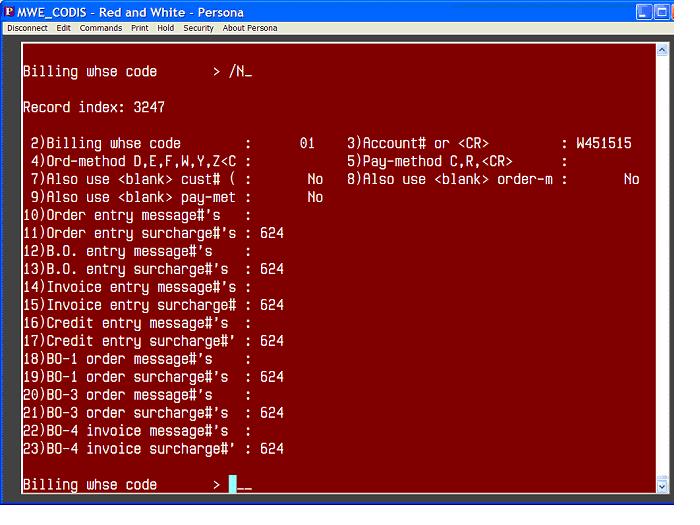

Setup a Surcharge codes

record that will be used to discount the entire amount (100% - see field #6) of

the kit invoice whenever there is a difference between the cost of the

components and the kit cost thereby producing a $0.00 invoice so as not to

affect accounts receivable.

Setup an “Order Add-on”

codes record associating the “ITU” customer number with the “Surcharge” number.

Here’s an example:

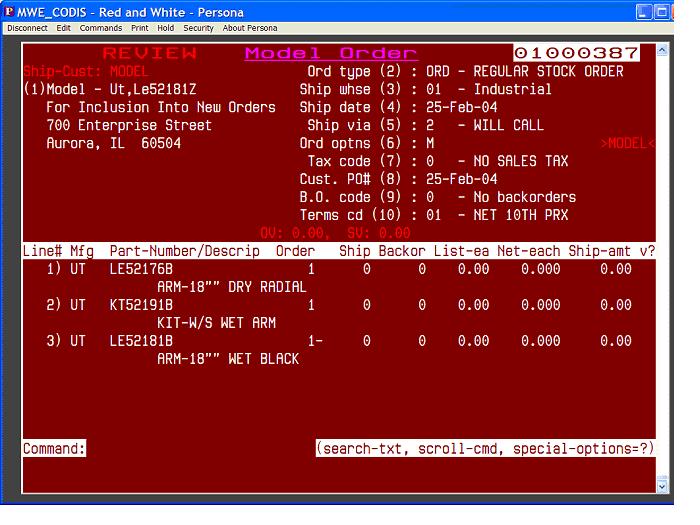

Create the model order for

building the kit. When creating the

model order be sure to give the model order a synonym that will be used when

keying the subsequent pick tickets that will be issued to the warehouse for

building the kits. For example, you are

building a “mini pallet” of oil

therefore you could use a synonym of BS,MP1 (whereas BS represents the

manufacturer code and MP1 represents the synonym). Key the components and respective quantities

that go into the kit. Key the kit part

but enter a negative quantity. The net

result is the kit model removes the component numbers from stock and adds the

kit number to stock when the pick ticket is finished through the

exceptions/invoicing program.

Here’s an example:

To recap:

When you key a pick ticket

for “